has become a popular flooring choice in both new and old homes, batches, workplaces, industry, retail and showrooms.

Concrete polishing is a practical and versatile flooring solution leaving you with a durable functionable floor.

This creates a classic look featuring clean lines which is durable and easy to clean.

Dependent on your space we can suit most budgets and give you the best advice on your area.

What makes polished concrete so special is that every floor is completely unique determined by many factors such as cement mix, stone, oxides etc.

With a new build you have the unique opportunity to determine some of these factors before the concrete is placed.

For expert and quality concrete polishing Auckland wide please do not hesitate to contact us at A N Concrete Polishing.

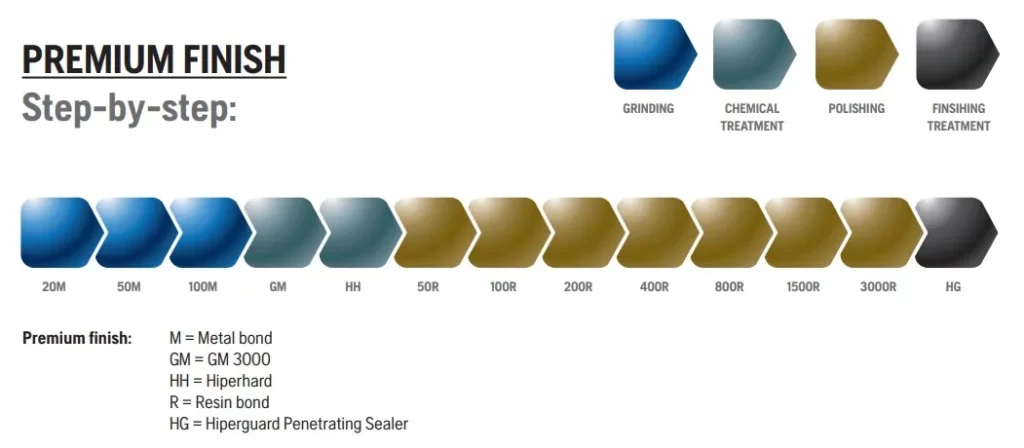

The chart below shows a step by step flow through each stage of the grinding and polishing process starting at 20 grit to a sealed & burnished finish. (we can also apply different sealers with different characteristics).

Some steps can be missed or others added in to suit your affordability and finish type.

There are many options when talking about polishing concrete here are a few of the main finishes that can be achieved.